[Lee, Daniel]

We are designing a custom ring to fit around the 1.0005" diameter, 2 mm thick cylindrical mirror for the GQuEST End Mirror Correction Mount. We ideally have an end mirror that clamps the entire ring of the end mirror. The current design has the ring ID of 0.998", 0.0025" smaller than the mirror it's clamping.

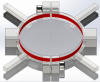

I think the current design clamps the mirror too tightly where the clamps meet and too loosly away from the joint. In SolidWorks, I moved the half rings 0.010" apart, the thickness of some indium foil from McMaster. I then checked where the ring and half rings overlap. See attached photo; overlap in red. Ideally, the rings have no overlap with the mirror when seperated by 0.010" and instead overlap everywhere by a few thou when the seperation is reduced.

I propose that instead of having a smaller ID, we shift the center of the ID out by (roughly?) half the indium foil size. This way, the mirror is not compressed when the indium foil is not compressed and the mirror is compressed everywhere when the screws are tightened. As the rings move in, the mirror edge furthest from the screws experiences the full change in distance while the edge of the mirror closest to the screws only has a fraction of the ring move into it. In some ways, I think this is good because the ring will bend in around the mirror by the screws, albeit not by much.