[Torrey, Daniel]

Torrey thinks that the central axes of the piezo and the mirror are misaligned. I designed a part that aligns the small piezo and a 1/4 in thick spacer with a #8 through hole with the "piezo top". This piezo top should be well aligned with the piezo bottom that holds the mirror. I believe this should give alignment of the axes to within ~5 thou rms (3 thou from the piezo top to the base, 4 thou from the mirror in the SM1 threads, and ~1 thou from this tool).

Attached is the part file with CAM as well. I decided to make this part in a CNC Lathe for its precision compared to a 3D print. An important consideration is the radius of curvature of the cutting tool. This is why there is a notch toward the thickest part of the tool and why the levels of the tool don't match the levels of each part. If one were to 3D print this part, they should remove the notch so that there are no overhung sections.

The blue colored photo is the CAM simulation.

I also made an alignment tool for a larger Thorlabs ring piezo. This requires a larger spacer, so I made a 1/4 thick (actually ~0.24 in) ring with a 1 in OD and ~0.358 in ID, slightly larger than the 9 mm ID of the ring piezo. This ring is aluminum because I didn't want to machine steel because it's tougher.

Attached is this file (medium) and STL files for this part and the other part.

I made this part on the CNC lathe and it fits well.

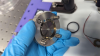

I also manually made a part to align the noliac piezo. This is essentially a 0.7" long rod with a 0.47" diameter and a 0.25" thick, 0.5" diameter cap so the rod doesn't go all the way into the piezo assembly. There isn't a part file for this.

This Noliac part was too large. The noliac ID appears to be closer to 0.463"

I made a piezo alignment tool for the Noliac NAC2125-H08. The diameter of this tool is 0.460" and it fits pretty smoothly around the piezo. Attached is the SolidWorks File (with CAM as well) and the file as an STL.

The Noliac piezo is a bit loose around the 0.46" diameter part, so I printed a conical version. I would have printed a version with a smaller conical angle, but I was worried about getting the part stuck because a 1-3 degree taper is prone to getting stuck.