[Briana, Ian]

On 8/5, we took data of the error signal. It is not possible to export the exact error signal you lock to since lock assist mode doesn't have this feature. Because we need 3 channels to be exported, we attached the temperature and photodetector output to the Moku Go, took readings of the error signal and photodetector output with the Moku Pro, and shifted the two so they overlapped in time. Then, the temperature scan, photodetector signal, and error signal could match up reasonably well and we could calibrate the time axis to wavelength. The temperature scan signal is noisy so I fit a line to it when calibrating because the calibration becomes messed up from the noise. Once this is done, we take the linear portion of the error signal (shown in orange in the following plot: error_signal_wavelength.png) and determine the slope (since it passes through the zero point). For the wavelength x-axis error signal, the slope is -1.976 V/nm (makes sense with the error signal: if I get an error signal of 0.002 V, I am detuned ~0.001 nm from resonance). The same can be done when we convert wavelength to frequency, which should technically be easy (f = c/wavelength) except it causes problems in the noise spectrum as I will explain later: error_signal_frequency.png. For the frequency converted x-axis error signal, the slope is 4.19 e-12 V/Hz. This is all under the assumption that the error signal generally has the same shape/slope in the linear region across scans.

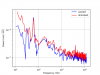

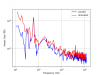

On 8/6, we took the power spectral density plots when the laser is locked and unlocked using the spectrum analyzer. The PSD was taken in two chunks with averaging over 6 samples because at lower frequencies (longer wavelengths), DC noise begins to broaden the spectrum (more room for error in the location of zero points of the wave during detection) so we had to zoom in from 0-100 Hz to get better resolution. Also, with the slow controller, we have a bandwidth of about 3 Hz (anything above will prevent the laser from locking, signal starts oscillating rapidly), which is not great. We took a PSD ranging from 0-10 kHz to cover the controller band. We want to increase the bandwidth (I frequency) of the slow controller so we can get a proper noise spectrum that is less cluttered by DC noise.

If we just look at these PSDs, we have no metric for how the different voltage ("power") readings correspond to frequency drifts (the y-axis aka power in V/sqrt(Hz) tells us the noise amplitude per frequency bin, but we don't have a good understanding of what this voltage means in terms of noise). So, we use the slope of our error signal to convert the voltage into frequency units (e.g. Hz/sqrt(Hz)), which gives us frequency noise (the linear region passes through the zero crossing point of resonance so we just need the slope as the "linear equation" in terms of detuning is slope * delta_wavelength, where delta_wavelength is the distance from resonance). We use the linear region because beyond the two "peaks," the controller will continuously push the laser frequency away from resonance (in the linear region the slope at the same error signal value would have the opposite derivative compared to the value outside of the peaks, so it pushes the frequency towards resonance instead of away).

To convert this PSD spectrum to a frequency noise spectrum, we multiply the original power value (V/sqrt(Hz)) by the inverse of slope. The frequency noise spectrum with y-axis in nm/sqrt(Hz) is here: Noise_Spectrum_wavelength.png. There is some distinction between the locked and unlocked case at the lower frequencies but this could also be because of noise fluctuations. On the bright side, the locked case has kind of lower noise. We would benefit from moving to higher frequencies in the controller, I'm still not entirely sure how to do this. The noise spectrum with the power axis in Hz/sqrt(Hz) is here: Noise_Spectrum_frequency.png. The order of magnitude for the frequency spectrum is definitely wrong but I have been unable to find the error so far because the slope from the error signal along with the conversion from wavelength to frequency makes sense to me (getting 0.002 V from the error signal means the frequency is detuned from resonance by ~10^12 Hz, for reference the frequency at 780 nm is around 3.8*10^14 Hz). If anything, there may be a differential (df/dlambda) involved because we are dealing with power, but I don't see a reason why f = c/wavelength shouldn't work. Anyways, I would trust the noise spectrum using wavelength for now. As a note, we used the slopes of the 8/5 error signals to convert from V/sqrt(Hz) to nm/sqrt(Hz). In the future, it will be better to use the error signal from the same measurement time as PSDs. There is a lot of systematic error here but we currently want a rough order of magnitude noise spectrum that makes sense.

One sanity check for the error signal is that we expect the unlocked scenario to drift more in frequency. When we look at the standard deviation of both error signals (unlocked and locked) using 8/5 data, convert the error signal voltage to a frequency away from the zero point, we get approximately 1.27 MHz for the locked case and 2.76 MHz for the unlocked case. This intuitively makes sense that the error signal would show that the laser has more deviation from the zero point (resonance) when not locked.

When I refer to unlocked, it means that after we have locked the laser, we break the connection between the controller and temperature scan and let the system do its thing at the fixed temperature at which resonance occurs.

Other notes/things to check tomorrow:

- Current setup: pump path is not really aligned but we will finish measurements before working on that. IMG_2405.jpg

- Triggering data logging could be the way to collect data from three channels: New in Moku v3.1.1: Triggered data logging start acquisition (liquidinstruments.com). Would mean we don't need the Moku Go but haven't figured out how to work this yet.

- Why can't we use the Phasemeter? Did we take PSDs of the error signal or photodetector signal?

- I also had attempted to create the PSD from taking the Fourier transform of the error signal. The resolution is not great in the region we need (0-100 Hz) but I'd like to try this method again because technically I should get the same result as the spectrum analyzer (I'm not).