This is a continuation of LeeLog 12105. TLDR - Teraxion laser is fully installed and functioning correctly except for the modulation port required to lock a cavity.

We put the swap on hold as a result of there being no internal Faraday Isolator in the teraxion seeder. Lee mentioned this should be fine for the short term. We plan on buying an isolator soon. In the mean time we should be fine to run this test.

Notes for the swap:

-Powered down amplifier. Turned off Thorlabs seeder.

-Secured laser module to the breadboard.

-Connected the module via USB extension to the BREWSTER computer. Connected fiber output to the power meter via fiber adapter. Turned power on.

-Installed the teraxion LXM laser control GUI on the BREWSTER computer.

-We successfully turned on the laser via the LXM laser control software. Note the software has an interlock system with a password, this password is 1234 and can be found in the manual. The initial output of the laser is 45mW as seen in the photo. I have concerns with controlling the laser via this little GUI. I don't know how closing the program or disconnecting the USB effects the continuous operation of the laser. This is important to ensure that no damage is done to the amplifier. We may test how easy it is to disrupt operation of the laser module before connecting to the amplifier. Testing in the software, there is no "are you sure button" when disabling the output. One click disables it.

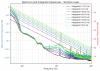

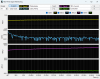

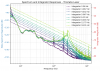

-The laser has ADCs and a popout in the software to track parameters of the laser like TEC current, laser temp, etc. See adc.png.

-I decided to test the continuous operation of the laser. Click the "Exit" button in the bottom right of the software does not disrupt lasing. I will assume that the laser will not shut down unless commands in the software are giving. This alleviates my worry outlined above.

-I plan on replacing the fiber PBS with a 75:25 fiber BS. This means one laser will have significantly reduced output. I need to double check the nominal output of the thorlabs laser to see if output*.25 is high enough to properly seed the amplifier.

-Replaced the fiber PBS with the 75:25. The output for the thorlabs seeder after the :25 path in the fiber beam splitter is ~10 mW (using the power meter, this value will change for the amplifier threshold power detector), which is most likely below the required input for the amplifier. Reminder: "Turn the Key ON: if the input power is lower than the pre-determined lower threshold power (typically 10-20 mW), there is an Alarm LIP (low Input Power), otherwise the preamplifier turns ON." Alternatively, we can swap the outputs of the fiber BS to avoid any alarms. The white output fiber should be used for the teraxion, the red output fiber for the thorlabs. Otherwise just getting one of these but a 50:50 would avoid having to ever swap any fiber connections. This is recommended.

-The teraxion is now seeding the amplifier. The power meter read 30.3 mW, the amplifier seeder is reading 27 mW. Both of the values are above the threshold. Continuing with turning on Amplifier.

-Turned key and hit enable on amplifier. The amplifier is now in pre-amplification mode. ~300 mW at the output, seeded by the teraxion.

-There is no 775 light. No light seems to be exiting the SHG. I suspect the wavelengths of the 2 lasers are different enough that the temperature controller needs to be tuned to the proper temperature for the SHG. I don't need 775 light for this test however so I will just note it and move on. Alternatively the wavelength of the laser can be tuned via a temperature controller. You most likely can tune to the same wavelength as the thorlabs controller so the SHG temperature controller doesn't have to be touched.

-The last step is we need to be able to modulate on the new laser. The manual says "please refer to the device test sheet to determine if your laser module accept ±2.5 V input or 0-4 V". Our test sheet on the wiki says +/- 2.5V. If using the moku this will never be a problem as we can't operate above +/- 2V in MIM anyways.

-Connected a moku output to the modulation port of the teraxion laser via patch panel and SMA adapter.

-Everything is connected. Scanning 2 V pp on the modulation port doesn't flash the cavity. I don't think anything is actually scanning. The scan amplitude is .2 GHz. The FSR is 125 MHz. Even at half the scan range we should see something. I tuned the temperature controller to have the cavity naturally flashing, and then turn on the modulation scan and still don't see anything. Manual shows a diagram connected to a waveform generator with a "10-100kHz" signal. Changed the scan frequency to this range, no change. I confirmed the moku is outputting a voltage via T-ing off the output and checking on a different scope. There is a triangle wave.

-Not sure what else to try so I checked the Ultra Narrow Linewidth Mode that is unique to the LXM-U that we have. It works.