[Ian,Torrey]

In order to more stably lock the filter cavities, we have been in talks of taking cavity transfer functions to isolate any resonances to upload an invert version of the TF as a filter in the DFB. We have written a script to make this work. Here are the following steps:

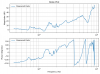

1) Take OFC TF. rawdata.png

2) Rescale the magnitude of the data so that it is 0 at low frequencies.

3) Invert it in complex form and choose the appropriate window for the filter. invertedandwindowed.png

4) Down sample the data to make the experimentally taken data smoother.

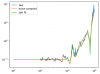

5) Fit the down sampled data to ZPK format. ZPKfit.png

6) Convert your ZPK curve into second order sections.

7) Write it to a text file in the format the moku wants. output.txt

success.png (I moved it down 20 dB so you can see the shape at high frequencies. This is done with the leading single digit on its own line in the text file.)

Some notes associated with this:

-The moku can only upload 4 SOS in this format as a custom filter. Limits the amount of shape we can add to our filter dramatically.

-We will upload this script to the log in a cleaner format but for now here it is piezoTF_calculation.ipynb. Its really messy though, we'll update with a cleaner version soon.

I tightened the remaining 2 flanges to steel to steel contact at 34 Nm.