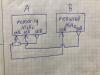

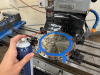

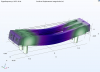

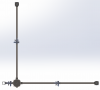

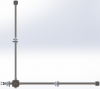

I machined 25 1/4-20 holes into a Kurt J Lesker F1000X000N, 10" diameter 304 Stainless Blank Flange. I added a 0.020" deep channel between the holes so that screws and posts wouldn't create virtual leaks if placed on top of one.

See attached photos and drawing.

Here is a list of instructions, some of which may only make sense to me:

Put flange on mill

Tape copper gasket at 45°, 135°, 225°, and 315° to secure it

Tape around copper gasket

Secure flange with 4 “stairs” with copper under the piece

Use 5/16 or 19/64 pieces to align leak checker gaps vertically

To do this, put 5/16 or 19/64 pieces holes and press against the rails

Finder center with edge finder

Program hole pattern

Use center drill to do hole pattern, going into the “2nd layer”

Use drill stop to do this

200 rpm on low speed and in reverse

Use #7 drill (.201 diameter) very tightly in chuck

Put in hole, use drill stop, raise drill, raise table 500 thou

Drill pattern using spray bottle lubricant

*use lots of pressure* and

700 rpm on high speed, forward

Use 4 flute, 90° chamfer tool

Put in hole, use drill stop, raise drill, raise table 50-65 thou

Chamfer using spray bottle lubricant

200 rpm on low speed, reverse

Program end mill pattern

*be sure to constantly raise and lower height*

Put 1/8 in diameter, 4 flute tungsten carbide end mill in, find 0 z by putting end mill over hole, barely taking anything

Then lower by 0.020” for channel

4000 rpm on high speed, forward

10”/min

Use initial (p) tap to get first pattern

Use bottom tap to clean up holes

Should get 14 half revisions out

This gives around .4” of depth

Carefully chase holes with bolts to clean up the thread

Use stone to remove burrs from end mill

Clean machining lubricant off flange