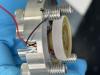

I cleaned the exterior of the following parts for the Laser Filter Cavity (LFC) using isopropanol and Kim wipes. Some tape and tape residue remains, so a more aggressive cleaning agent might be required before we bring the parts into B102 to clean the insides. See attached photos for the parts I cleaned.

Parts cleaned for LFC:

8" to 6" reducing Tee, 12" Long

6" Gate Valve (quantity 2)

End Cube and End Cube Base (quantity 2)

8" diameter bellows, 5" long (probably needs more clenaing before we bring it to B102)

Long 10" to 8" Reducer "flange"

Short 10" to 8" Reducer flange

Misc 10" Flanges

I also cleaned the following parts attached to the above parts that are not needed for the LFC:

An additional 8" to 6" reducing Tee, 12" Long

6" diameter flange, 12" long tube (quantity 2)