[Jeff, Torrey]

We setup a fiber EOM and a REFL PD to set up a PDH lock on the auxillary 1550 path to the second filter cavity. This will give consistent 1550 light leaving filter cavity 2 in order align and mode match into filter cavity 3.

First, we added a mirror to direct the reflected 1550 beam to a Newport 1811 photodiode. This mirror is cramped against the imput mirror and is very close to clipping the input beam. We used a lens and an ND filter to focus onto the PD and prevent saturation. The REFL dip is not very low, suggesting the cavity is not critically coupled or we have alignment issues. Additionally, the old 900ish Hz oscillations are seen on this photodiode signal. Even though we are not using the Thorlabs laser, this is expected because the whole drawer is sharing ground with the Thorlabs laser. Hopefully this can be resolved by swaping out the Thorlabs power supply.

Next we installed a fiber EOM on the OFC 2 1550 test path. The RF drive required a SMP connector, which was borrowed from the LIGO lab from Todd Etzel.

There was initially a large optical loss through the EOM, this was addressed by adding a half waveplate at the fiber input of the test path on the power distribution sled and rotating the polarization to maximize transmitted power.

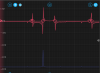

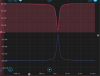

After tuning up alignment a bit, we achieved a lock of OFC 2 on 1550, actuating on the Teraxion laser.

We unplugged the Thorlabs laser so it is completely off, and this removed to 900Hz noise and improved the lock.