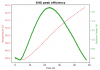

While considering vibrations of the coldhead and what to do if they're problematic for the interferometer, an idea occured to me to cool the conductive bar as a reservoir, turn off the cold head, and then the beam splitter will slowly cool down from 123 K to 122 K and then heat up to 124 K. In order to tune this temperature, we would need to in situ remove ~95% of the conductivity from the bar to the cold breadboard. This remaining conduction would have to be pretty accurate as well. I consider a 10 kg copper reservoir and the two "best" coldheads, the Sumitomo CH110 which has a lot of cooling power, and the Cryomech PT30RM which has a fair amount of cooling power but should have minimal vibrations. In summary, this is a vialbe option if we can do two challeneing things: change the conduction between the bar and the cold breadboard in situ and turn the coldhead on and off a few times per day.

In addition, I looked into two other tricks to help us: increasing the mass of the cold breadboard and thermally linking the cold breadboard and the inner shield to provide additional time. The former does help the duty cycle and increases the warmup time while the latter has a worse duty cycle with minimal benefit over just cooling more mass.

Modeling data below:

Hot inner shield, 4 kg cold breadboard:

CH110:

6:09:57 to cool everything initially

Get 7:33:57 before the breadboard hits 124 K, takes 0:04:39 to reset breadboard, 34:58 to reset bar to within 1 K of equilibrium (duty cycle = 0.94)

PT30RM:

13:54:56 to cool everything initially

Get 6:08:26 before the breadboard hits 124 K, takes 0:10:43 to reset breadboard, 4:03:00 to reset bar to within 1 K of equilibrium (duty cycle = 0.6)

Hot inner shield, 20 kg cold breadboard:

CH110:

26:09:36 to cool everything initially

Get 15:42:36 before the breadboard hits 124 K, takes 0:24:30 to reset breadboard, 0:45:37 to reset bar to within 1 K of equilibrium (duty cycle = 0.95)

PT30RM:

44:28:12 to cool everything initially

Get 11:45:47 before the breadboard hits 124 K, takes 1:14:48 to reset breadboard, 4:56:26 to reset bar to within 1 K of equilibrium (duty cycle = 0.70)

Cold inner shield, 4 kg cold breadboard:

CH110:

23:49:17 to cool everything initially

Get 17:57:21 before the breadboard hits 124 K, takes 3:55:45 to reset the breadboard, 12:22:07 to reset the inner shield to within 1 K of equilibrium (duty cycle = 0.6)

PT30RM:

43:15:39 to cool everything initially

Get 16:09:28 before the breadboard hits 124 K, takes 9:00:23 to reset breadboard temp to 123 K, 15:02:13 to reset the inner shield to within 1 K of equilibrium (duty cycle = 0.5)